Currently Empty: $0.00

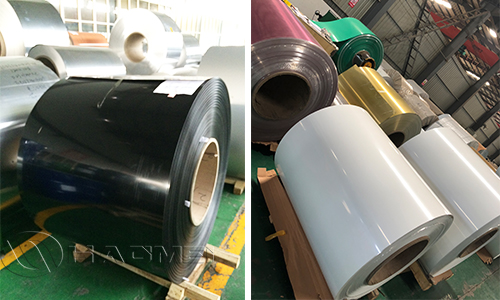

1050 color aluminum coil for name plates

Name plates are a typical application of the 1050 color aluminum coil. 1050 aluminium contains 99.% aluminium, featured by low hardness, good corrosion resistance and cheap price. As any other pure aluminum alloy, its production process is quite mature in China. It’s impossible for mill finish 1050 alu coil to serve as a name plate material, for its corrosion resistance, although good, is relatively poor in this application field. After being color coated, 1050 coil gets improved in surface quality and service life, becoming a favorite name plate material of many purchasers.

Typical tempers for name plate 1050 color aluminum coil include H42 and O, though other tempers like H12, H14, H16, H22, H24, H32, H34, H36, H44 and H46 are also available. The typical thickness is 1.0mm, but the thickness range supplied by Haomei is 0.8mm to 2.0mm. Thicker rolls are available, too. The width of the coil is 10mm to 1800mm. The coil weight and inner diameter can be customized. The coating thickness for one-coat is 18+/-2um and two-coat 25-28um, with a 5-10um back coat. Colors can be customized by RAL or your sample. Special specifications could be customized.

1050 color aluminum coil is applied to the name plate making for several reasons. First, it’s light in weight. Aluminium is the lightest of the three common industrial metals. Being light is a big advantage as a name plate material. Second, it’s good in corrosion resistance. Color coated 1050 aluminum coil has an even better corrosion resistance. The paint coating adheres firmly to the plate even in severe conditions. Third, it’s easy to process it. The 1050 aluminum has a good plasticity, suitable for name plating making processes like stamping and printing. Fourth, it’s of good cost efficiency. As said above, the production technology is very mature now, which helps to reduce the production cost substantially. Further more, there is sufficient aluminium in the crust shell, and there’s no need to worry about the resource.