Currently Empty: $0.00

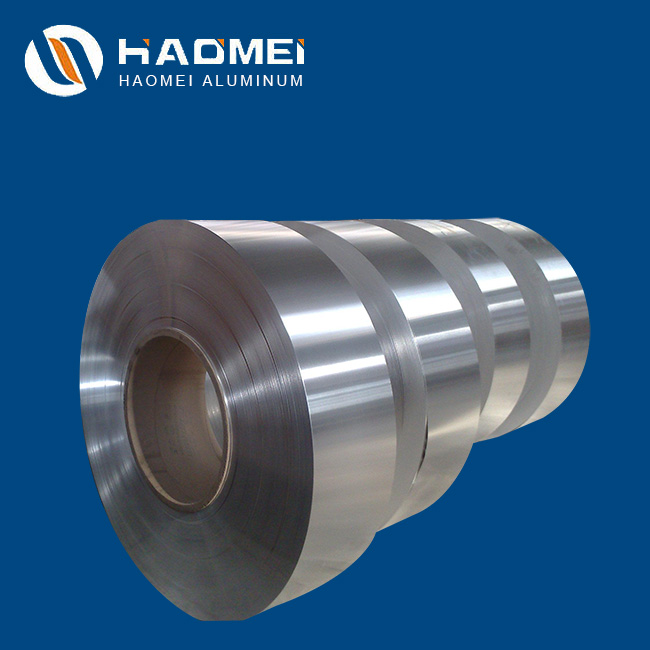

Usual Problems in Welding of 7075 Aluminum Strip

Processing technology of 7075 aluminum strip has developed rapidly with continuous market demand. However, problems still arise in practical manufacturing process. Owing to the fact that aluminum is featured by strong oxidation property, low melting point, high heat conductivity, big coefficient of liner expansion and large latent heat of fusion, workers may meet some technical problems in the welding process.

The liner expansion coefficient of 7075 aluminum strip is twice that of carbon steel or low alloy steel. As a result, it has shrinkage, porosity, cracks and high internal stress during the welding process. This problem can be solved by adjusting welding stick composition and soldering process. Aluminum silicon sticks can be used for welding of alloys except 5000 series of aluminum alloys. When the silicon content surpasses 0.5%, 7075 aluminum strip has larger hot cracking tendency, which decreases with increase of silicon content. In accordance with our manufacturing experience, the best silicon content should be between 5% and 6%. If we choose aluminum silicon sticks with 4.5% to 6% silicon content, there is great possibility that the strip will not crack at all. Besides, 7075 aluminum strip gets oxidized easily and produces Al2O3 during the welding process. Al2O3, with high melting point and stable properties, proves hard to be removed. Therefore, the surface of the strip must be cleaned completely with chemical or mechanical methods before it’s welded. Alternating current power supply should be applied for argon tungsten-arc welding to clean Al2O3 by the negative pole. With gas welding there are special cleaning agents.