Currently Empty: $0.00

Manufacturing Process of Aluminum Strip

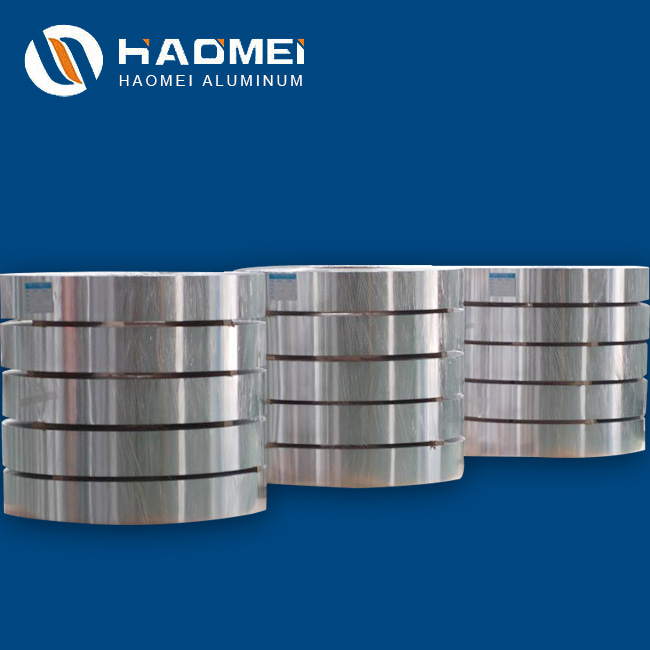

Aluminum strip refers to deep-processing products of aluminum coil. Obtained by cutting aluminum coil into narrow strips, it’s a crucial kind of raw material in manufacturing industry. Based on content ratio of different metals in aluminum strip, it can be classified into 8 series, among which the most commonly applied are 1000, 3000, 5000 and 8000 series. In accordance with temper states, there are O (soft), H24 (half hard) and H18 (hard). In comparison with the other two states, O is more popular, because it shows better tensile strength. The manufacturing process is as below.

Briefly speaking, strip-cutting machine set produces aluminum strip of given length and width. Be to specific, the manufacturing process include hot rolling, cold rolling, heat treatment as well as finishing. Hard alloy of complex chemical elements should go through homogenizing treatment before being hot rolled. The alloy is normally kept for 12 to 24 hours at a temperature between 10 and 15℃. There are singular stand hot rolling and multiple-stand hot rolling. Aluminum strip by hot rolling can be 6 to 8mm thick. Manufactures with more advanced equipment can supply products of 2.5 to 3.5 thick. Cold rolling, a process of normal temperature, makes the size preciser, the surface smoother and the force properties more satisfying. Relative equipment include hydraulic bending roll and automatic thickness control system. Then the half-finished aluminum strip goes to straightening machines for finishing, which should be done with around half an hour after quenching.

Haomei Aluminum has decades of manufacturing experience and over ten years of exporting history. We supply aluminum strip for transformer, cables, blind windows etc. In addition to common specifications, we also accept customization. Welcome to contact us at april@aluminumhm.com for more information!