Currently Empty: $0.00

How are Aluminum Discs Processed into Pots

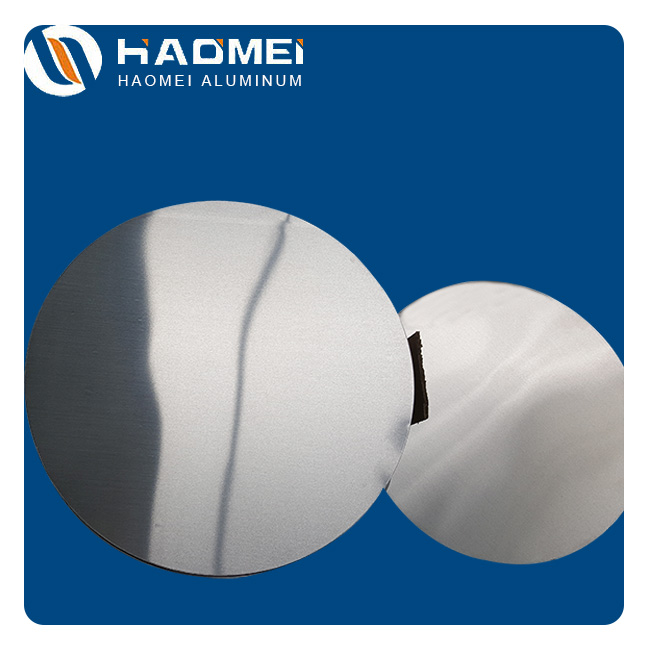

According to a series of industrial statistics, almost half of cookware in the world are of aluminum discs. And by cookware here we mainly refer to pots. Although kettles takes up some share of aluminum disc consumption as well, it can not even compete with pots. If you have seen aluminum circles, you may agree that they are only pieces of round aluminum sheets. Then, how are these round sheets, processed into three-dimensional pots without any cracks or wrinkles?

A video of pot production clearly show process from aluminum discs to pots. A piece of aluminum circle blank is placed into a machine. The edge of the circle is then fixed and a column stretched out to push the disc into the shape of a pot, the bottom of which is of the same shape and size with the column. It takes only seconds to finish the process. As a matter of fact, the video shows only one step of manufacturing process. Complete process include aluminum discs feeding, deep drawing (as shown in the video), edge finishing, bottom flattening and cleaning. The feeding step entails choosing material first. Only discs of top quality are allowed to go into processing machines. In deep drawing, as shown in the video, aluminum discs are turned into the rudiments of pots like stretchy rubber. There are no cracks or winkles on the surface of finished pots, because aluminum circles have excellent tensile strength and shrinkage force, which make them withstand stretches evenly. Edge finishing involves making the edge of a pot into desired shape of a given size. Bottom flattening refers to make the bottom of a pot flat, or into a certain shape. As for cleaning, it means clean the whole finished pot before packing it.

Based on the information above, we can conclude that aluminum discs are processed into pots thorough discs feeding, deep drawing (as shown in the video), edge finishing, bottom flattening and cleaning. To manufacture pots of top quality, you must first obtain excellent aluminum discs. Why not contact us at alu@aluminio.cn for more information?